-

tel:

+86 13773014250 -

email:

jinjiang@kinkou.cn

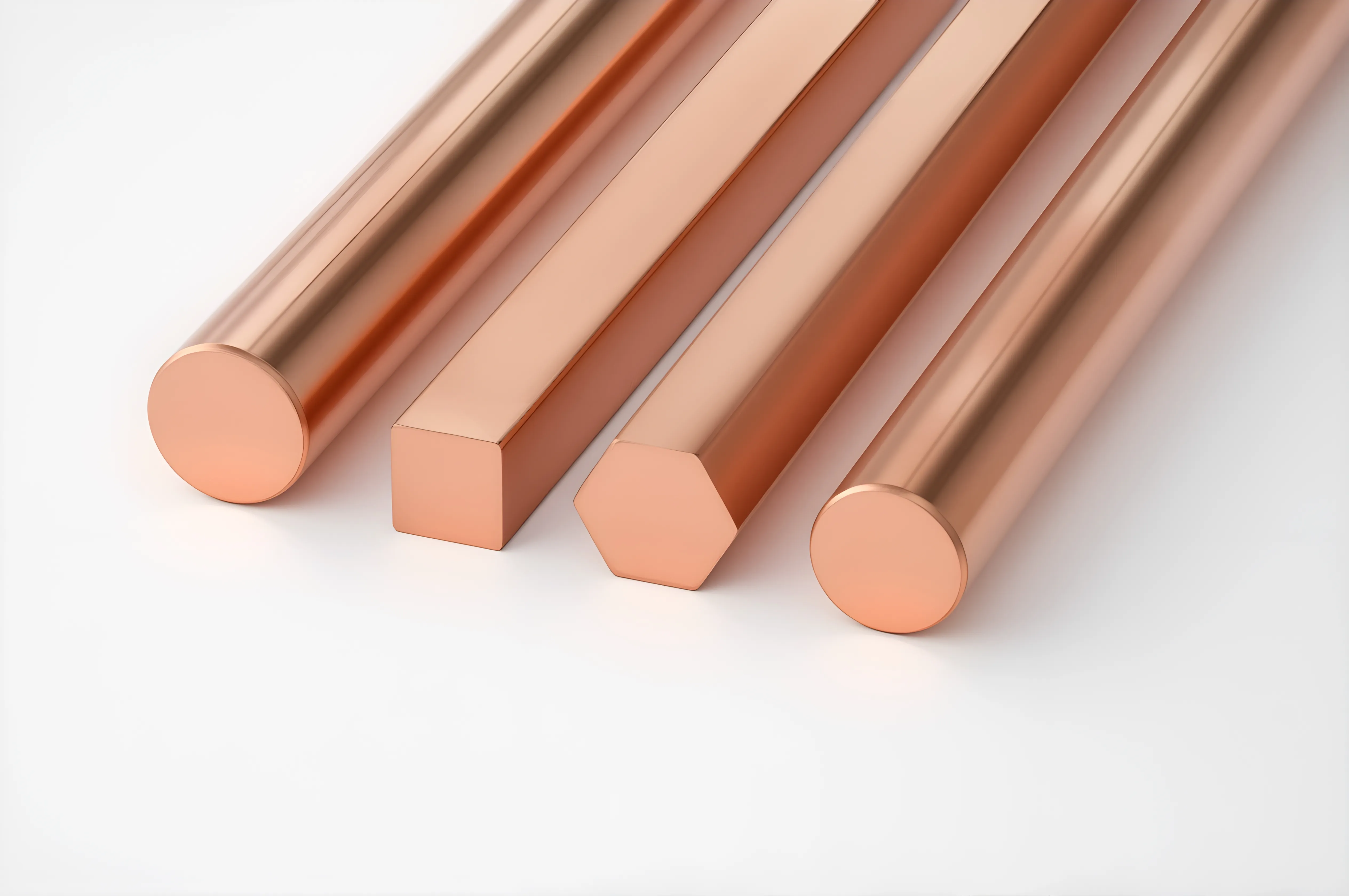

Copper Cobalt Beryllium Rod

EN: CuCo2Be

UNS: C17500

Standards: ASTM B441 (rods/bars)

Quick Detail:

C17500 alloy is a precipitation-hardened beryllium-cobalt copper alloy renowned for its exceptional balance of high strength, electrical/thermal conductivity, and corrosion resistance.

Rod size from Dia.1mm - Dia.75mm

Key Characteristics & Advantages:

Corrosion Resistance:excellent in seawater, freshwater, and atmospheric conditions (corrosion depth: 0.01–0.14 mm/year)35. Resists sulfuric acid (<80% concentration) but vulnerable to ammonia/nitric acid36.

Special Characteristics:Non-magnetic, spark-free on impact. Retains properties from cryogenic (−196°C) to elevated temperatures (300°C).

Machinability: 20–40% of free-cutting brass (requires carbide tools with cooling).

Formability/Weldability: Excellent cold/hot workability (e.g., forging, extrusion). Compatible with TIG, laser, electron beam, and brazing techniques

| Chemical composition (wt,%): | |||||

| Be | Co | Al | Fe | Si | Cu |

| 0.4-0.7 | 2.4-2.7 | <0.2 | <0.1 | <0.2 |

Rem. |

Physical and Mechanical property:

| Temper | Tensile Strength | Hardness |

Eletric Conductivity |

||

| ksi | MPa | HV0.5 | HRB | %, IACS | |

| TB00 Solid Solution Treatment |

33-35 | 240-380 | 88 | >50 | >20 |

| TD04 Solid Solution Treatment & Cold Process Hardning |

65-80 | 450-550 | 107-148 | 60-80 | |

| TF00 Precipitation Heat Treatment |

100-130 | 690-895 | 192-230 | 92-100 | >45 |

| TH04 Precipitation Hardening |

110-140 | 760-965 | 200-260 | 95-102 | >48 |

Core Applications:

Electronics: Connectors, relay springs, switch components.

Welding Equipment: Electrodes for spot/seam welding (especially stainless steel/high-nickel alloys).

Mold Tooling: Injection mold cores, blow-molding inserts (exploits thermal conductivity for rapid cooling).

Aerospace/Marine: Fasteners, bearings, submarine cable repeaters (due to seawater resistance).

_美图抠图07-08-2025.webp?x-oss-process=image/resize,w_100/quality,q_100)

_美图抠图07-08-2025.webp?x-oss-process=image/resize,w_100/quality,q_100)